Technology

You are reading about TECHNOLOGY | Skip to QUALITY >

The historic symbiosis between

cork and wine goes back centuries.

Throughout the years, expertise, wisdom, and experience have been accumulated and put to use to increasingly improve cork closures and their ability to preserve precious liquids. Technology, especially, has played a big part when it comes to said improvements.

At Lafitte, we work tirelessly to innovate, creating new ways to sustainably protect each bottle of wine with TCA and aroma-free cork stoppers, so that every moment is as perfect as possible. After all,

It's all about perfection.

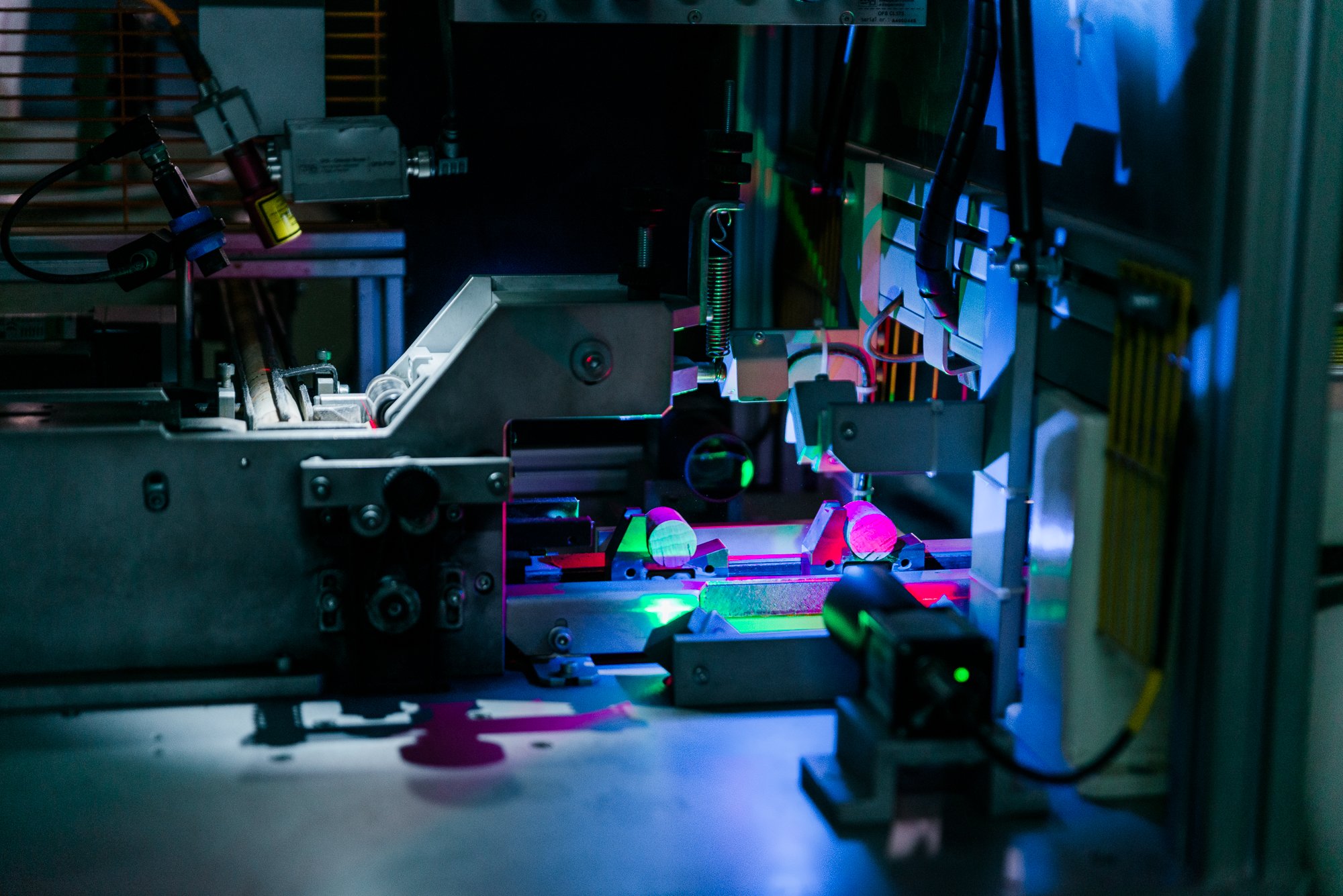

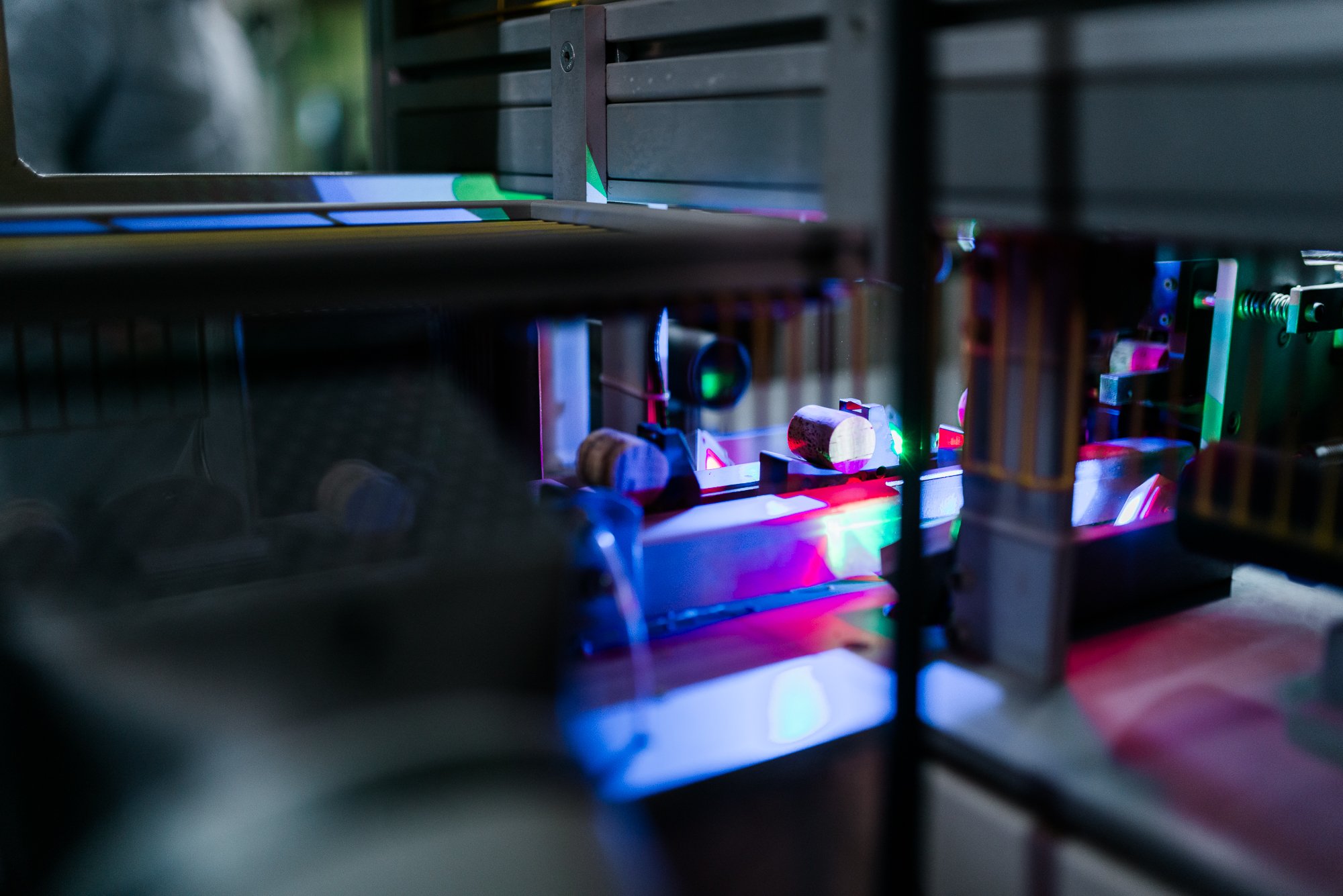

Perfect Go

Our PerfectGO technology allows for the individual analysis of cork stoppers, measuring the TCA level of each stopper, even below detection limit, in a non-invasive way, thus creating 100% TCA-free batches.

The alliance between PerfectGO technology and the natural qualities of cork stoppers guarantees the perfection of each bottle, honoring the sacred ritual of opening a great bottle of wine.

Max Clean Evolution

Max Clean Evolution is a two-phase sterilization and deodorization system that, through pressure, dry steam, temperature, and time, produces natural cork stoppers free of any aromas and, even better, TCA-free.

LD21

This technology was developed and manufactured specifically to verify the tightness of natural cork stoppers and discard the stoppers that do not comply with the values established by the client.

Laser Branding

Our laser branding machines are the latest innovation in the cork closure branding market. This new technology is offered in addition to ink and fire branding, and ensures high resolution branding on all cork closures types.

Laser branding does not require most of the materials used in the process of ink and fire branding, such as stamps, ink, solvents and other cleaning products and, furthermore, reduces the production and delivery time. This makes it - undoubtedly - the most efficient and sustainable way of leaving your mark.

Molding machine

Our molding machine allows us to create the best microaglommerated cork stoppers in the market. The cork bodies are produced by injecting a mixture of cork granulate and natural binders in individual molds.

Once inside the molds, the mixture is compressed and submitted to extreme temperatures - both hot and cold - to solidify its final shape. With Lafitte, you’re guaranteed a stable, visually appealing and structurally homogeneous product.